It started as a whisper — a subtle shift in Toyota’s North American strategy that barely made headlines. But inside boardrooms in Washington, Detroit, and Raleigh, alarms were going off. Because what looked like a simple expansion into Canada was actually the first visible sign of a tectonic realignment in the continental auto industry — a move that could reshape the future of EV manufacturing across North America.

And it all began with a single truth Toyota could no longer ignore:

The United States had become too unpredictable to build the future in.

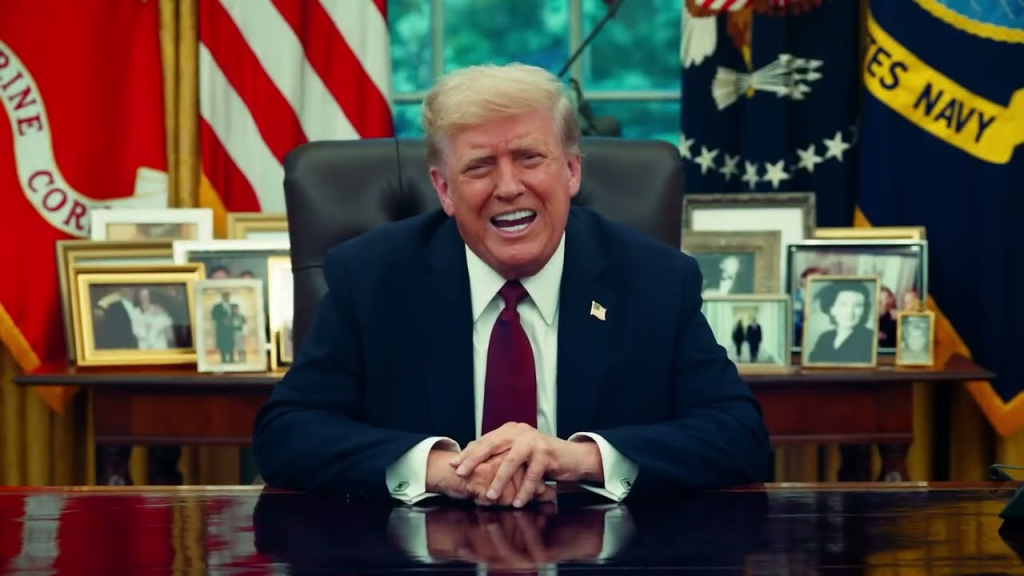

For decades, Toyota treated the U.S. as its industrial anchor. Massive factories, tens of thousands of jobs, and billions invested into the American manufacturing landscape. But by 2024, that foundation had cracked. Tariffs under the Trump administration alone put nearly $800 billion in potential losses on Toyota’s balance sheet. Currency swings stripped away billions more. Steel, battery materials, and imported components spiked in price overnight.

Then came the profit warning:

Toyota projected a 21% decline heading into 2025.

Executives couldn’t pretend anymore. The world’s most disciplined automaker was being forced into chaos by a system that changed rules faster than factories could adjust.

The breaking point came when Toyota’s U.S. EV production plan — once slated to surge in Kentucky — stalled again. Deadlines pushed. Permits delayed. Costs rising. Suppliers couldn’t meet the Inflation Reduction Act’s strict requirements. And without compliant battery materials, Toyota risked losing billions in tax credits tied to its electric lineup.

Meanwhile, on the Mexico border, another threat appeared: potential penalties for how Tacoma trucks were assembled. Suddenly Toyota found itself designing cars not for consumers — but for the political maze of U.S. trade law.

Behind the scenes, panic grew.

And that’s when Canada stepped into the light.

Canada Had What the U.S. Didn’t: Stability

While the U.S. scrambled to reconcile laws, tariffs, and shifting definitions of “compliance,” Canada quietly built a full-spectrum EV corridor stretching through Ontario and Quebec. Unlike the U.S., Canada wasn’t just offering incentives.

It was offering certainty.

Critical minerals? Canada has cobalt, nickel, lithium — and the refining capacity the U.S. still lacks.

Regulatory clarity? Ottawa delivered long-term rules that matched EV investment cycles.

Supply chain integration? Toyota could feed parts directly into Michigan and Ohio without crossing oceans or navigating surprise tariff announcements.

And the game-changing development:

North America’s only operational cobalt refinery — First Cobalt Corp — was rising in Ontario.

It would produce IRA-compliant battery materials the U.S. simply could not supply.

Inside Toyota’s leadership circle, the math became undeniable.

Every Canadian investment lowered future risk.

Every U.S. delay increased it.

The New EV Power Corridor Was Taking Shape

Quebec’s battery plants.

Ontario’s mineral refineries.

GM’s massive cathode material investment.

Honda’s multibillion-dollar EV hub.

Then Toyota began quietly expanding its presence across the corridor, deepening partnerships, securing minerals, and aligning its long-term EV architecture with Canadian infrastructure. No dramatic press conference. No sweeping declarations.

Just a steady, strategic migration north.

Suddenly U.S. officials — from Tennessee to Texas to North Carolina — realized Toyota’s shift wasn’t symbolic.

It was structural.

Washington’s Panic Was Immediate

Governors who once boasted about landing Toyota facilities began asking hard questions:

Is Toyota relocating future EV jobs to Canada?

Will U.S. training programs and subsidies go to waste?

Is America losing its manufacturing edge?

Behind closed doors, congressional briefings were tense. Some lawmakers accused Toyota of using Canada as a “compliance shield” to keep access to U.S. customers while avoiding U.S. political chaos.

But Toyota didn’t waver.

Its executives repeated the same message:

Stability creates investment.

Unpredictability kills it.

And stability — in minerals, rules, and long-term EV planning — existed only in Canada.

A New Automotive Map Is Emerging

Toyota’s move signaled what analysts now call the Continental Realignment. A moment when Canada, not the United States, became the most attractive home for EV supply chains.

The reason wasn’t ideology.

It wasn’t labor.

It wasn’t taxes.

It was something far simpler — and far more powerful:

Canada built the EV system Toyota needed.

The U.S. did not.

If America fails to close the gap in refining capacity, policy consistency, and supply chain integration, Toyota may be only the first domino to fall.

Because once a corridor begins drawing manufacturers, momentum takes over — and companies follow stability like water follows gravity.

Toyota didn’t abandon the U.S.

But it chose Canada for the future.

And that choice is shaking the entire continent.

Leave a Reply